3D Printing Write for Us

3D Printing Write for Us – If you’re interested in writing a guest post for 3D Printing, you’ve come to the right place! Our blog, The Techies Blog always on the lookout for writers interested in 3D Printing who can provide fresh content for our blog. Writing for us will help you gain experience, enrich your resume, and promote your name on one of the leading websites on 3D modeling. Furthermore, sharing links to your site will improve its Domain Authority.

It is frustrating to see that quality 3D printing reviews or brilliant 3D design projects are only limited to a particular social media group. At the same time, it is not the most straightforward task to start a website for a broader online audience; it is time and resource-consuming. The Techies Blog offers an opportunity to publish 3D design and 3D printing-related content, which will benefit authors by giving them extra publicity and other bonuses.

Types of Articles Categories We Accept

The topics include technology, small business, cyber security, digital marketing, Information/News, 3D Printing For Education, artificial intelligence (AI), education, blockchain, fashion, sports, social media, SEO, hosting, gadgets, computers, hardware, apps/reviews, marketing, and business blogging, startups, entrepreneurship, and entertainment.

How To Submit An Article?

To Submit Your Articles, you can email us at contact@thetechiesblog.com

What Is 3D Printing?

3D (Three-dimensional) Printing is an additive manufacturing process that generates a physical object from a digital design. The method works by laying down thin layers of material in liquid or powdered plastic, metal, or cement and then fusing the layers.

Essential Points Of 3D Printing?

- 3D Printing is a preservative manufacturing process in which a physical object originates from a digital design by printing thin layers of material and then fusing them.

- Some industries, such as hearing aids, airline, and car manufacturers, use 3D Printing to create prototypes and mass produce their products using custom scans.

- While it is currently too slow to work in mass production, 3D printing technology is still evolving and can potentially massively disrupt the manufacturing logistics and inventory management industries.

What is 3D printing material used for?

Compounds such as carbon fiber manage in 3D printers. As a top coat over plastic things, the purpose is to strengthen the plastic. The combination of carbon fiber over plastic uses in the 3D printing industry as a fast, appropriate alternative to metal.

Types of 3D Printing Technology

The term 3D printing encompasses numerous manufacturing technologies that build parts layer-by-layer. Each varies in how they form plastic and metal parts and can differ in material selection, surface finish, durability, manufacturing speed, and cost.

There are numerous types of 3D Printing, which contain:

Stereolithography (SLA)

It is the original industrial 3D printing process. SLA printers excel at producing parts with high levels of detail, smooth surface finishes, and tight tolerances. It’s general uses in the medical industry and typical applications include anatomical models and microfluidics. We use Vipers, ProJets, and iPros 3D printers manufactured by 3D Systems for SLA parts.

Selective Laser Sintering (SLS)

SLS melts together nylon-based powders into solid plastic. Since SLS parts are of actual thermoplastic material, they are durable, suitable for functional testing, and can support living hinges and snap-fits. Many SLS parts work for prototyping designs that will one day be injection-molded. For our SLS printers, we use sPro140 machines developed by 3D systems.

PolyJet

PolyJet is another plastic 3D printing process, but there’s a twist. It can fabricate parts with multiple properties, such as colors and materials. Designers can leverage the technology for prototyping elastomeric or over-molded features. If you’re prototyping an over-molding or silicone rubber design, PolyJet can save you from investing in tooling early in the development cycle. It can help you iterate and validate your design faster and save money.

Digital Light Processing (DLP)

It is similar to SLA in that it cures liquid resin using light. The primary difference between the two technologies is that DLP uses a digital light projector screen, whereas SLA uses a UV laser. DLP 3D printers can simultaneously image an entire build layer, resulting in faster build speeds.

Multi Jet Fusion (MJF)

Like SLS, Multi Jet Fusion also builds functional parts from nylon powder. Rather than using a laser to sinter the powder, MJF uses an inkjet array to apply fusing agents to the bed of nylon powder. Then a heating element passes over the bed to connect each layer. Another benefit of the MJF process is the accelerated build time, which leads to lower production costs.

Fused Deposition Modeling (FDM)

It is a standard desktop 3D printing technology for plastic parts. An FDM printer functions by extruding a plastic filament layer-by-layer onto the build platform, and it’s a cost-effective and quick method for producing physical models. There are some instances when FDM comes under functional testing, but the technology is partial due to parts having relatively rough surface finishes and lacking strength.

Why Write for The Techies Blog – 3D Printing Write for Us

What Are We Looking For?

We want to find writers passionate about 3d printing and would like to share their exciting views on 3d printing and any news they find valuable. The Techies Blog is looking for like-minded people to help filter through all the noise in the space and highlight the most valuable content to readers.

Things we would like to see:

- Creative and exciting views on anything related to 3d printing

- Valuable insights into the use and application of 3d printing

- Analyses of news and events going on in the 3d printing space

- Information about the ever-evolving 3d printing regulations of various jurisdictions

- Content related to technical areas of 3d printing is hugely welcome.

What We Don’t Accept

1- Posts that have been published already in some other place.

2- Posts that are unorganized or have an unclear focus.

3- The paragraph should not be too long, around 5 to 6-line sections in the article, and it is easy to understand and preferable for us and the audience.

Correctness, Readability, Plagiarism, and Performance

Before submitting your article for review, kindly ensure it’s correct and easy to read. Use tools like Grammarly or any other you prefer to check your performance of yourself and those reading it – after all, we want interested people! Once submitted with this information included, our team will do their best not only at checking content but also plagiarism, which means if there were instances of theft they’ll be caught red-handed with no excuse.

Search Terms for 3D Printing Write For Us

thingiverse

3d printing software

write for us photography

wifi “write for us”

mobile phones “write for us”

inurl: write for us

mobile networks “write for us”

technology “write for us”

technology blogs that accept guest posts

5G blogs “write for us”

telecom blog write for us

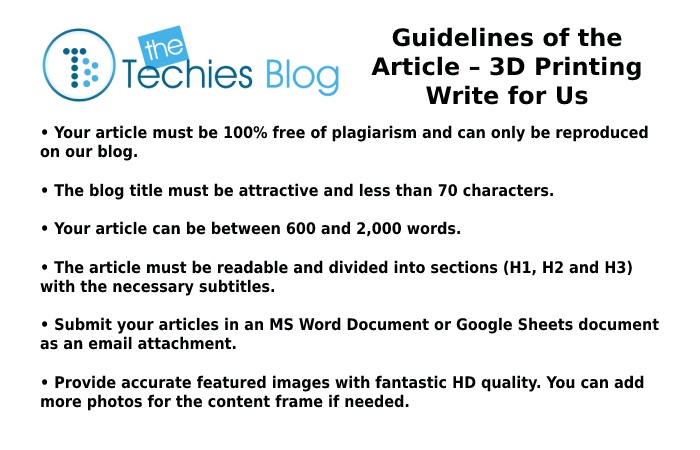

Guidelines of the Article – 3D Printing Write for Us

We’ve prepared the following guidelines for you to find out the style and content we can accept on our blog.

You can send your article to contact@thetechiesblog.com

Related Pages: